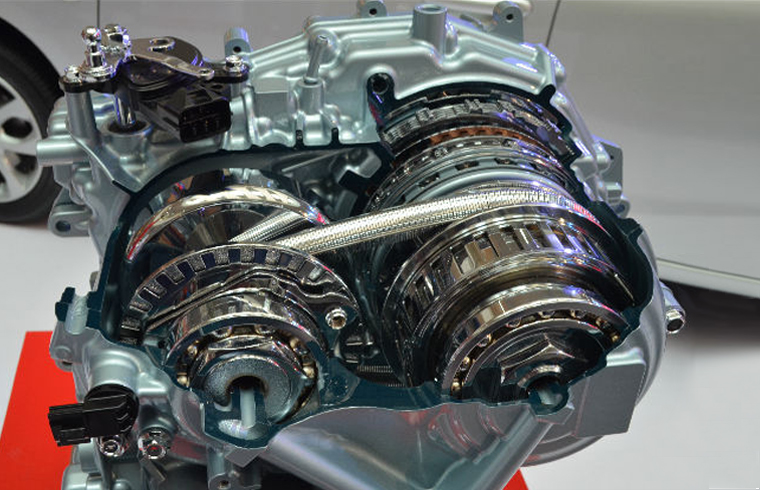

In Cvt pulleys Perform an important role as being the conical form pulleys integrated more than enter and output shafts are the reason for continuously variable transmission’s steady n-range of speed and gear ratios, on account of the various cross segment of these conical pulleys various torque and velocity ratios are attained.

Although CVTs have significant advantages and disadvantages, so do other transmission sorts. Finally, CVTs are in this article to remain, a minimum of until finally EVs stage them out with an identical shiftless knowledge due to their one-pace transmission setups. As with transmission evolutions with the past — from handbook to automated and now to CVT — many people take pleasure in the new technological know-how, and many resist it as lengthy as you can.

These pros are supported by serious-planet facts and case reports from various industries, demonstrating the part of CVTs in boosting vehicle efficiency and performance. By featuring improved fuel performance, toughness, and Regulate, CVTs are significantly favored by both equally companies and motorists.

그래서 차량 제조사에서 오히려 변속 느낌을 일부러 만들어 주는 경우도 있다.

CVT transmissions run to the theory of maintaining the motor at its exceptional speed, generally known as the "energy band," for optimum effectiveness. Here's a simplified clarification in their operation:

CVTs give additional useable power, better fuel financial system along with a smoother driving knowledge than conventional transmissions that use gearboxes with preset figures of equipment sets.

CVTs stick out from common transmissions due more to their exclusive power to change seamlessly by way of an infinite amount of effective gear ratios among utmost and minimum values.

Exact same as relocating enter pulley but in contrast to relocating enter shaft, this shaft is put on the right-hand side over the output shaft.

No Gear Shifts: The absence of equipment shifts usually means a lot less tension on transmission factors, contributing to a longer lifespan and possibly decreased upkeep expenditures.

A CVT is usually additional economical than its conventional counterpart, at the least in terms of fuel discounts, by trying to keep the car or truck’s engine velocity normally in the best put at the proper time.

Some cone CVT patterns use two rollers.[22][23] In 1903, William Evans and Paul Knauf used for any patent with a constantly variable transmission working with two parallel conical rollers pointing in opposite directions and related by belts that could be slid along the cones to range the transmission ratio.

At its core, the CVT employs an easy nonetheless refined mechanism involving belts and pulleys that alter their diameter since the car or truck moves. This adjustment will allow the transmission to alter the motor’s output velocity without the need of interruptions from changing gears.

An computerized transmission diagram is a visual illustration of the different factors which make up an automatic transmission system….

The overall variety of mechanical parts in a very CVT is more compact than in a typical Earth-gearset transmission. Devoid from the popular phalanx of gears and cogs, a CVT box employs a brace of adjustable conical pulleys attached to the steel chain or belt.